Turkish hot melt adhesive supplier's background:

This supplier of hot melt adhesives was established in 2008 and is based in Istanbul, Turkey. Hot melt adhesives supplier specializes in manufacturing and supplying adhesives, solvent-based adhesives, and pressure-sensitive adhesives. Turkish hot melt adhesive offers a wide range of hot melt adhesives, including EVA-based, polyolefin-based, and metallocene-based adhesives.

Their hot melt adhesives are used in various applications, such as packaging, bookbinding, woodworking, and automotive. They provide customized solutions to meet the specific requirements of their customers. Hot melt adhesives supplier is committed to providing high-quality products and services to its customers.

The company has a team of experienced engineers and technical specialists who work closely with customers to understand their needs and provide tailored solutions. They have a modern laboratory with advanced equipment for glues product testing and development. It is focused on innovation and continuous improvement. The company invests in research and development to develop new products and improve the performance of its existing products. They prioritize sustainability and environmental responsibility, using raw materials that are eco-friendly and recyclable.

As a wholesaler, you should know that hot melt adhesives have several key features that make them popular in industrial settings. These thermoplastic materials are solid at room temperature, but when heated to a molten state, they become liquid and can be easily applied to various materials. Once used, they quickly cool and solidify, forming a strong bond between substrates.

Hot melt adhesives are known for their fast setting speed and high bonding strength, making them ideal for use in applications requiring a quick turnaround time. They can bond with a wide range of materials, including plastics, paper, and textiles, and are designed to provide a strong, durable bond that can withstand various environmental conditions.

One of the main advantages of hot melt adhesives is that they are solvent-free, which makes them environmentally friendly and safe to use. Additionally, these adhesives are available in various formulations, each designed to meet specific bonding needs. They can be used in packaging, woodworking, and automotive applications.

Hot melt adhesives are easy to use, and because they are applied in a molten state, they can bond irregularly shaped substrates. They are also resistant to moisture and other environmental factors, making them ideal for industrial use.

Hot melt adhesives are:

A popular choice for manufacturers and wholesalers alike.

Thanks to their versatility.

Ease of use.

Strength.

Hot melt adhesives are worth considering if you are looking for a reliable adhesive solution for your industrial applications:

Hot melt adhesives (HMA) are thermoplastic adhesives that melt to a liquid state when heated and solidify upon cooling to form a strong bond. The following are different types of hot melt adhesives based on their composition and properties:

EVA (ethylene-vinyl acetate) hot melt adhesive: made of a copolymer of ethylene and vinyl acetate and used in packaging, bookbinding, and woodworking industries.

Polyamide hot melt adhesive: made of a nylon resin and used in the automotive, textile, and footwear industries.

Polyolefin hot melt adhesive: made of a polymer of propylene, ethylene, or a blend of the two and used in the packaging industry.

PUR (polyurethane reactive) hot melt adhesive: made of a polyurethane prepolymer and a curing agent and used in automotive, construction, and woodworking industries.

Pressure-sensitive hot melt adhesive: characterized by an aggressive initial tack and used in applications such as labels, tapes, and stickers.

Metallocene hot melt adhesive material : made of a metallocene-based polymer and used in the packaging industry for carton sealing, case and tray forming, and tray erection.

Styrenic block copolymer hot melt adhesive: made of a styrene-butadiene-styrene or styrene-isoprene-styrene block copolymer and used in the footwear, automotive, and electronics industries.

APAO (amorphous poly-alpha-olefin) hot melt adhesive: made of a low molecular weight polymer and used in packaging, woodworking, and bookbinding applications.

Reactive hot melt adhesive: contains a reactive group that can crosslink with another reactive group to form a chemical bond and is used in the automotive and construction industries.

Polyethylene hot melt adhesive: made of a polymer of ethylene and used in the packaging industry for case and carton sealing and in the woodworking industry for edge-banding.

here's a table of characteristics of hot melt adhesive products for wholesalers:

Characteristic | Description |

Type | Hot melt adhesives |

Temperature range | Generally between 150°C to 200°C |

Polymers used | Ethylene-vinyl acetate (EVA), polyamides, polyurethanes, and others |

Solvent-free | Hot melt adhesives do not require solvents for application |

Solid content | Typically 100% solid content |

Surface bonding | Hot melt adhesives provide excellent surface bonding |

Application method | Applied in molten form and solidify on cooling |

Versatility | Hot melt adhesives can be used for bonding a variety of materials including plastics, fabrics, rubber, and porous materials |

Dispensing systems | Hot melt adhesives can be dispensed using bulk systems, handheld guns, and other technologies |

Stability | Hot melt adhesives have excellent stability and can maintain their properties for extended periods |

Mechanical properties | Hot melt adhesives can provide excellent mechanical strength and durability |

Specialty products | Hot melt adhesives are available in specialty formulations for specific applications |

Waxes | Hot melt adhesives can contain waxes to modify properties such as open time and viscosity |

An example with numbers:

Characteristics | type product A | product B | product C |

Softening Point ( temperatures ) | 85°C | 92°C | 78° C |

Viscosity (cps) | 4,500 | 3,800 | 5,200 |

Color (APHA) | 50 | 10 | 25 |

Open Time (sec) | 15 | 25 | 10 |

Set Time (sec) | 30 | 45 | 20 |

Shear Strength | 120 psi | 140 psi | 100 psi |

Peel Strength (N) | 20 N | 25 N | 15 N |

Heat Resistance | Good | Great | Fair |

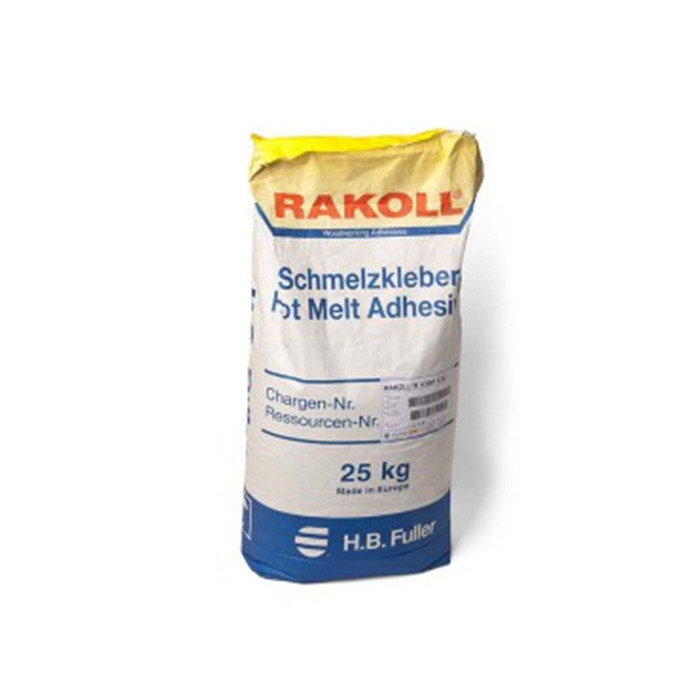

Packaging Wholesale Hot Melt Adhesives for Maximum Efficiency:

Packaging hot melt adhesives for wholesale requires careful consideration of the product’s unique properties. Hot melt adhesives are thermoplastic adhesives applied in a molten state and solidify upon cooling to form a bond. The adhesive is heated to a temperature range of 121-177°C (250-350°F) and has a bonding time of 2-60 seconds. Industrial hot melt adhesives are polymer-based, solvent-free formulations that provide fast bonding strength and have a wide range of substrates.

When packaging hot melt adhesives for wholesalers, the frequency and score of the unique properties must be considered. Packaging should be designed to provide maximum efficiency, including easy access and storage. One way to package hot melt adhesives is by creating individually wrapped sticks. This method ensures that each glue stick is kept at a consistent temperature until it is ready for use, preventing the adhesive from drying out. Sticks also allow for easy handling and application, providing faster bonding times. Packaging should be labeled with a clear indication of the adhesive's properties, including its temperature range, bonding time, and substrate range, to ensure that the adhesive is applied correctly.

Maximizing storage efficiency is critical when packaging hot melt adhesives. To achieve this, the packaging should be designed to accommodate the frequency and score of the adhesive's properties. The packaging should be sturdy enough to withstand industrial settings and protect the glue from environmental factors such as water and heat.

The packaging should also include the appropriate cooling system, ensuring that the adhesive cools and solidifies after application. Furthermore, the packaging should be designed to minimize waste, emphasizing recyclable materials and providing an eco-friendly solution to packaging hot melt adhesives for wholesale.

General shipment information for this hot melt adhesive company:

This hot melt adhesives and glue factory has fast shipment services. Shipment is available worldwide. Packaging is sustainable and secure. All vendors can complete shipment paperwork. The supplier has reasonable shipment fees. The hot melts will be properly placed to prevent cargo damage. The MOQ of this glue supplier is 10 pcs.

General payment information for this hot melt adhesive supplier:

This windshield supplier has simple payment terms. Payment is available by cash or telegraphic transfer (wire transfer). Payment ways will suit all vendors. The supplier provides hot melt adhesives at good prices. Try start to increase your profit.

Kahruman provides direct purchases from proper factories. This helps vendors to receive the best wholesale adhesives prices offered. Shop now and easily contact Kahruman.com, the top hot melt adhesives wholesaler.

Looking for a reliable partner for your wholesale hot melt adhesive needs? Look no further! Our top-quality hot melt adhesives supplier offers unbeatable performance and consistency, all at competitive wholesale prices. Contact us today to learn more and join our loyal customer base. Let's grow our businesses with kahruman, top-of-the-line hot melt adhesives and solids products, and exceptional customer service.

Hot Melt Adhesive Supplier: Solvent-Free Adhesives for Safe Use

- Country of Origin: Türkiye

- Payment type: TT - Cash - Wire Transfer

- Availability: out of stock

- Brand: AET

- SKU: 49725

Similar products

Customers who purchased this item also bought these

Turkish hot melt adhesive supplier's background:

This supplier of hot melt adhesives was established in 2008 and is based in Istanbul, Turkey. Hot melt adhesives supplier specializes in manufacturing and supplying adhesives, solvent-based adhesives, and pressure-sensitive adhesives. Turkish hot melt adhesive offers a wide range of hot melt adhesives, including EVA-based, polyolefin-based, and metallocene-based adhesives.

Their hot melt adhesives are used in various applications, such as packaging, bookbinding, woodworking, and automotive. They provide customized solutions to meet the specific requirements of their customers. Hot melt adhesives supplier is committed to providing high-quality products and services to its customers.

The company has a team of experienced engineers and technical specialists who work closely with customers to understand their needs and provide tailored solutions. They have a modern laboratory with advanced equipment for glues product testing and development. It is focused on innovation and continuous improvement. The company invests in research and development to develop new products and improve the performance of its existing products. They prioritize sustainability and environmental responsibility, using raw materials that are eco-friendly and recyclable.

As a wholesaler, you should know that hot melt adhesives have several key features that make them popular in industrial settings. These thermoplastic materials are solid at room temperature, but when heated to a molten state, they become liquid and can be easily applied to various materials. Once used, they quickly cool and solidify, forming a strong bond between substrates.

Hot melt adhesives are known for their fast setting speed and high bonding strength, making them ideal for use in applications requiring a quick turnaround time. They can bond with a wide range of materials, including plastics, paper, and textiles, and are designed to provide a strong, durable bond that can withstand various environmental conditions.

One of the main advantages of hot melt adhesives is that they are solvent-free, which makes them environmentally friendly and safe to use. Additionally, these adhesives are available in various formulations, each designed to meet specific bonding needs. They can be used in packaging, woodworking, and automotive applications.

Hot melt adhesives are easy to use, and because they are applied in a molten state, they can bond irregularly shaped substrates. They are also resistant to moisture and other environmental factors, making them ideal for industrial use.

Hot melt adhesives are:

A popular choice for manufacturers and wholesalers alike.

Thanks to their versatility.

Ease of use.

Strength.

Hot melt adhesives are worth considering if you are looking for a reliable adhesive solution for your industrial applications:

Hot melt adhesives (HMA) are thermoplastic adhesives that melt to a liquid state when heated and solidify upon cooling to form a strong bond. The following are different types of hot melt adhesives based on their composition and properties:

EVA (ethylene-vinyl acetate) hot melt adhesive: made of a copolymer of ethylene and vinyl acetate and used in packaging, bookbinding, and woodworking industries.

Polyamide hot melt adhesive: made of a nylon resin and used in the automotive, textile, and footwear industries.

Polyolefin hot melt adhesive: made of a polymer of propylene, ethylene, or a blend of the two and used in the packaging industry.

PUR (polyurethane reactive) hot melt adhesive: made of a polyurethane prepolymer and a curing agent and used in automotive, construction, and woodworking industries.

Pressure-sensitive hot melt adhesive: characterized by an aggressive initial tack and used in applications such as labels, tapes, and stickers.

Metallocene hot melt adhesive material : made of a metallocene-based polymer and used in the packaging industry for carton sealing, case and tray forming, and tray erection.

Styrenic block copolymer hot melt adhesive: made of a styrene-butadiene-styrene or styrene-isoprene-styrene block copolymer and used in the footwear, automotive, and electronics industries.

APAO (amorphous poly-alpha-olefin) hot melt adhesive: made of a low molecular weight polymer and used in packaging, woodworking, and bookbinding applications.

Reactive hot melt adhesive: contains a reactive group that can crosslink with another reactive group to form a chemical bond and is used in the automotive and construction industries.

Polyethylene hot melt adhesive: made of a polymer of ethylene and used in the packaging industry for case and carton sealing and in the woodworking industry for edge-banding.

here's a table of characteristics of hot melt adhesive products for wholesalers:

Characteristic | Description |

Type | Hot melt adhesives |

Temperature range | Generally between 150°C to 200°C |

Polymers used | Ethylene-vinyl acetate (EVA), polyamides, polyurethanes, and others |

Solvent-free | Hot melt adhesives do not require solvents for application |

Solid content | Typically 100% solid content |

Surface bonding | Hot melt adhesives provide excellent surface bonding |

Application method | Applied in molten form and solidify on cooling |

Versatility | Hot melt adhesives can be used for bonding a variety of materials including plastics, fabrics, rubber, and porous materials |

Dispensing systems | Hot melt adhesives can be dispensed using bulk systems, handheld guns, and other technologies |

Stability | Hot melt adhesives have excellent stability and can maintain their properties for extended periods |

Mechanical properties | Hot melt adhesives can provide excellent mechanical strength and durability |

Specialty products | Hot melt adhesives are available in specialty formulations for specific applications |

Waxes | Hot melt adhesives can contain waxes to modify properties such as open time and viscosity |

An example with numbers:

Characteristics | type product A | product B | product C |

Softening Point ( temperatures ) | 85°C | 92°C | 78° C |

Viscosity (cps) | 4,500 | 3,800 | 5,200 |

Color (APHA) | 50 | 10 | 25 |

Open Time (sec) | 15 | 25 | 10 |

Set Time (sec) | 30 | 45 | 20 |

Shear Strength | 120 psi | 140 psi | 100 psi |

Peel Strength (N) | 20 N | 25 N | 15 N |

Heat Resistance | Good | Great | Fair |

Packaging Wholesale Hot Melt Adhesives for Maximum Efficiency:

Packaging hot melt adhesives for wholesale requires careful consideration of the product’s unique properties. Hot melt adhesives are thermoplastic adhesives applied in a molten state and solidify upon cooling to form a bond. The adhesive is heated to a temperature range of 121-177°C (250-350°F) and has a bonding time of 2-60 seconds. Industrial hot melt adhesives are polymer-based, solvent-free formulations that provide fast bonding strength and have a wide range of substrates.

When packaging hot melt adhesives for wholesalers, the frequency and score of the unique properties must be considered. Packaging should be designed to provide maximum efficiency, including easy access and storage. One way to package hot melt adhesives is by creating individually wrapped sticks. This method ensures that each glue stick is kept at a consistent temperature until it is ready for use, preventing the adhesive from drying out. Sticks also allow for easy handling and application, providing faster bonding times. Packaging should be labeled with a clear indication of the adhesive's properties, including its temperature range, bonding time, and substrate range, to ensure that the adhesive is applied correctly.

Maximizing storage efficiency is critical when packaging hot melt adhesives. To achieve this, the packaging should be designed to accommodate the frequency and score of the adhesive's properties. The packaging should be sturdy enough to withstand industrial settings and protect the glue from environmental factors such as water and heat.

The packaging should also include the appropriate cooling system, ensuring that the adhesive cools and solidifies after application. Furthermore, the packaging should be designed to minimize waste, emphasizing recyclable materials and providing an eco-friendly solution to packaging hot melt adhesives for wholesale.

General shipment information for this hot melt adhesive company:

This hot melt adhesives and glue factory has fast shipment services. Shipment is available worldwide. Packaging is sustainable and secure. All vendors can complete shipment paperwork. The supplier has reasonable shipment fees. The hot melts will be properly placed to prevent cargo damage. The MOQ of this glue supplier is 10 pcs.

General payment information for this hot melt adhesive supplier:

This windshield supplier has simple payment terms. Payment is available by cash or telegraphic transfer (wire transfer). Payment ways will suit all vendors. The supplier provides hot melt adhesives at good prices. Try start to increase your profit.

Kahruman provides direct purchases from proper factories. This helps vendors to receive the best wholesale adhesives prices offered. Shop now and easily contact Kahruman.com, the top hot melt adhesives wholesaler.

Looking for a reliable partner for your wholesale hot melt adhesive needs? Look no further! Our top-quality hot melt adhesives supplier offers unbeatable performance and consistency, all at competitive wholesale prices. Contact us today to learn more and join our loyal customer base. Let's grow our businesses with kahruman, top-of-the-line hot melt adhesives and solids products, and exceptional customer service.

Shipping Information

Shipping Cost: Enjoy free shipping for orders exceeding 300 USD.

Available Countries: Our shipping services extend worldwide.

Shipping Time: Expect your order to arrive within 20 days after payment confirmation.

Taxation: Taxes vary for each product and country and are not included in our prices.

Container Quantities: Reach out to us for customized discounts and shipping information.

Return Information

Return Process: Should you need to return a product purchased from Kahruman, follow these steps:

- Initiate Your Return: Begin the return process by creating a request.

- Send Back the Product: Once your return request is approved, send the product back to the store.

- Store Refund: After the store approves the return, your refund will be processed.

- Receive Your Refund: Your refunded amount will be returned to your card.

Exercise your right of withdrawal for the products you've purchased from Kahruman. For any inquiries regarding products, feel free to contact the store through the "Ask a Question to the Store" section. To initiate a return, simply click to view the return process. Opt for the store's contracted cargo company to send back the product free of charge.

Please note that the exercise of the Right of Withdrawal and Return Conditions are governed by the provisions of the Consumer Protection Law No. 6502 and the Distance Contracts Regulation.

Lead time

Quantity (PCS) | 1 - 1000 | 1001 - 5000 | > 5000 |

Lead time (days) | 10 | 20 | To be negotiated |

Samples

Maximum order quantity: 100 PCS

Customization

- Customized logo

Min. order: 40 feet container

- Customized packaging

Min. order: 40 feet container

- Graphic customization

Min. order: 40 feet container

For more customization details, contact supplier

Ratings & Reviews

- Product reviews

- Store reviews

3.6/5 satisfied

Supplier service: 5.0

On-time shipment: 3.5

Product quality: 4.6